Introduction

Critical Minerals are of increasing concern to governments around the world, as geopolitical tensions and supply constraints have highlighted various economies' dependence upon them.

This dependence has prompted a number of moves and policy decisions by major players, which have, in turn, increased tensions.

Subsea Minerals have the potential to provide abundant volumes of Critical Minerals, from various jurisdictions around the globe. They therefore present an opportunity to decrease geopolitical tensions whilst underpinning the tech required for the green transition.

What are Critical Minerals?

Critical Minerals are naturally occurring substances that are essential to the economic and national security of many countries. They have significant importance in various industries, such as technology, energy, defense, and manufacturing.

"(Critical Minerals are) raw materials for which there are no viable substitutes with current technologies, which most consumer countries are dependent on importing, and whose supply is dominated by one or a few producers"

The exact definition of a critical mineral varies by country, depending on their specific economic and strategic needs, but some common characteristics of critical minerals include:

-

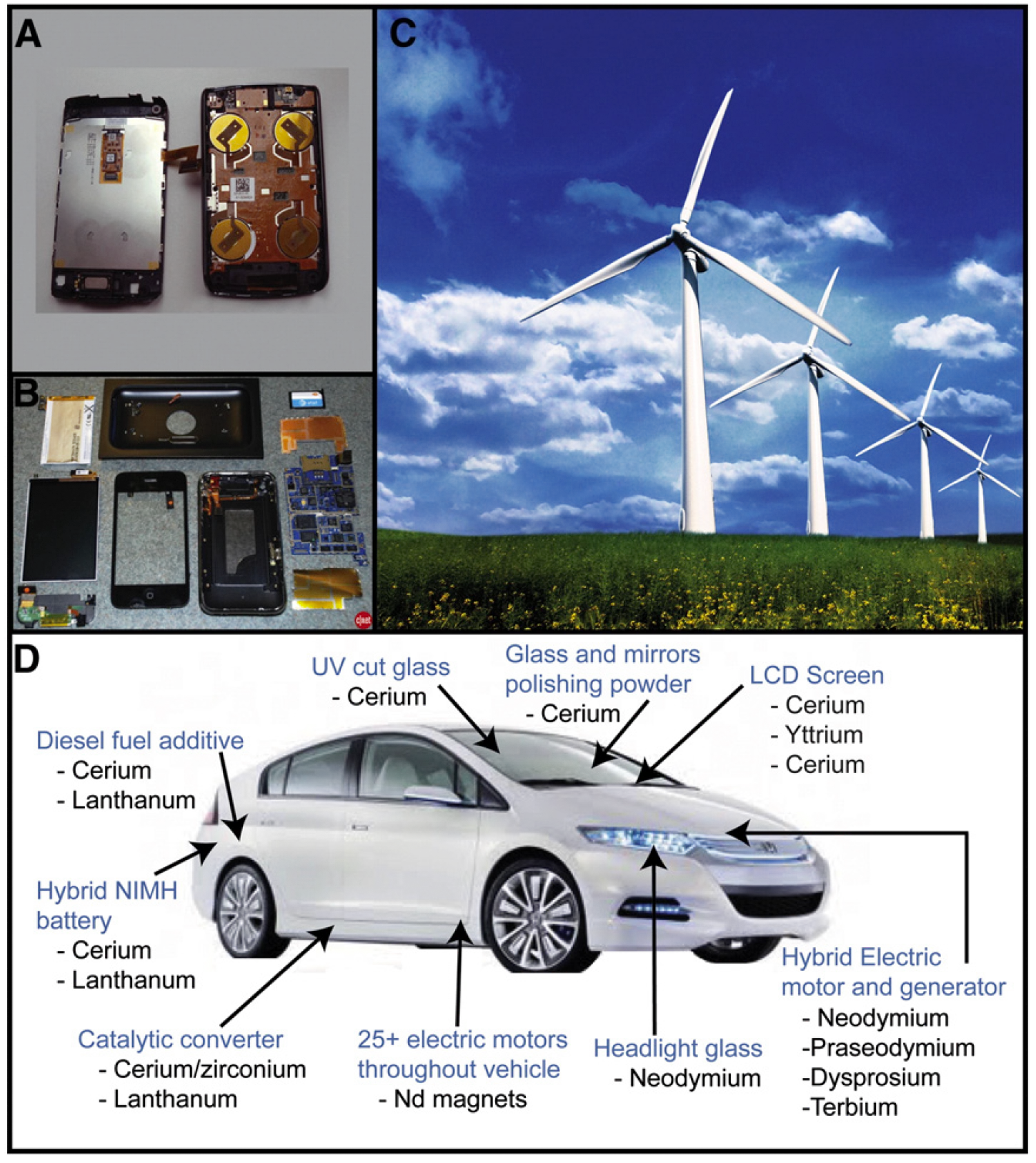

Economic Importance: certain critical minerals are vital for the manufacturing of high-tech products, renewable energy technologies, and other advanced industrial applications. For instance, rare earth elements are crucial for the production of permanent magnets used in wind turbines and electric vehicles.

-

Supply Risk: Many critical minerals are subject to supply risks due to various factors, such as geographic concentration of production, political instability in producing regions, trade restrictions, and limited recycling capabilities. For example, China dominates the global supply of many rare earth elements, which raises concerns for countries dependent on these materials.

-

Lack of Substitutes In many cases, there are no effective substitutes for critical minerals, making them irreplaceable in certain applications. This lack of substitutes further enhances their importance and the need to secure stable supplies.

The US Department of Energy's definitions are:

Critical Material: Any non-fuel mineral, element, substance, or material that the Secretary of Energy determines: (i) has a high risk of supply chain disruption; and (ii) serves an essential function in one or more energy technologies, including technologies that produce, transmit, store, and conserve energy; or

A critical mineral, as defined by the Secretary of the Interior.

Critical Mineral: Any mineral, element, substance, or material designated as critical by the Secretary of the Interior, acting through the Director of the U.S. Geological Survey.

Which Minerals are Critical?

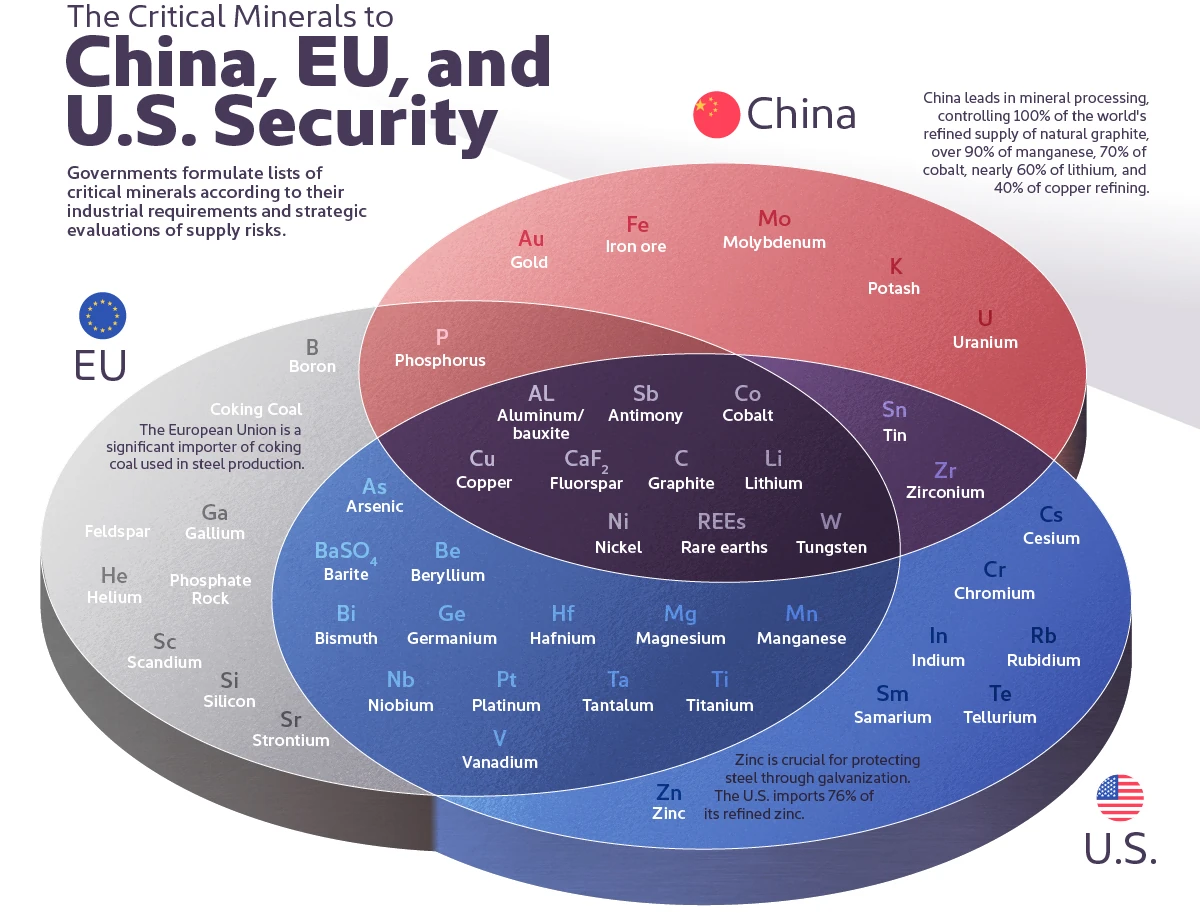

Geopolitics, supply/demand and the abundance of certain resources mean that the specific critical minerals vary by country (see images below), but some of the most commonly recognized critical minerals are:

- Rare Earth Elements (REEs): A group of 17 elements that are crucial for the production of high-performance magnets, batteries, and other electronic components

- Lithium: Essential for lithium-ion batteries, which are widely used in electric vehicles and portable electronic devices

- Cobalt: Used in rechargeable batteries and aerospace alloys

- Nickel: Important for stainless steel and batteries

- Graphite: Used in batteries, lubricants, and as a moderator in nuclear reactors

- Tungsten: Known for its high melting point and strength, used in metalworking, mining, and construction equipment

- Platinum Group Metals (PGMs): Includes platinum, palladium, rhodium, and others, essential for catalytic converters and various electronics

Source:

"Deep-ocean mineral deposits as a source of critical metals for high- and green-technology applications: Comparison with land-based resources"

James R. Hein, Kira Mizell, Andrea Koschinsky, Tracey A. Conrad

Ore Geology Reviews, Volume 51, 2013, Pages 1-14, ISSN 0169-1368

https://doi.org/10.1016/j.oregeorev.2012.12.001

For instance, Visual Capitalist shows the following overview of critical minerals between the 3 major blocs of the US, Europe and China:

Whilst there is tremendous overlap in some elements, such as Copper, Cobalt, Lithium, Nickel and REEs, there are also major differences between the blocs.

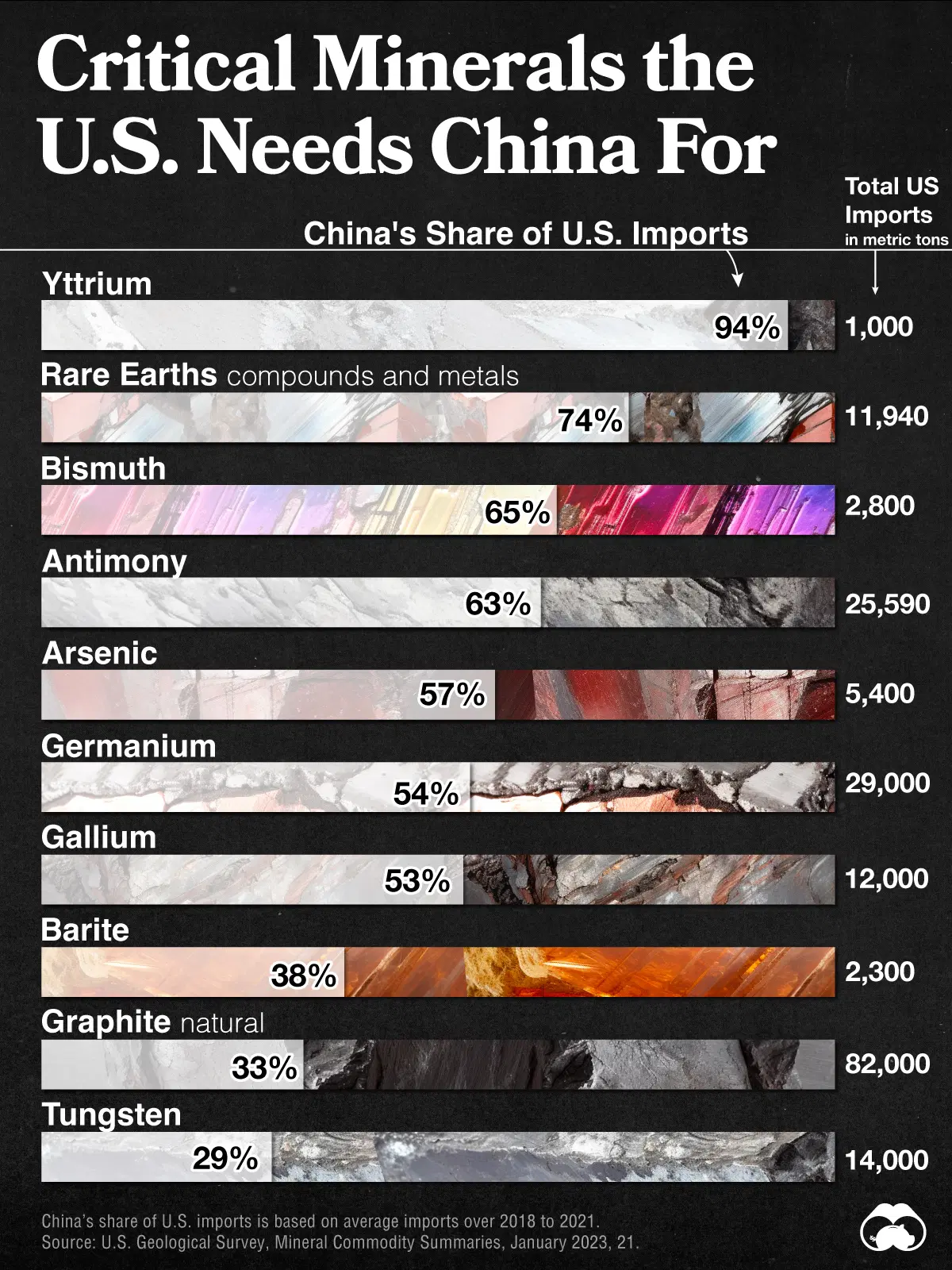

US Dependence Upon China

As discussed above, critical minerals vary by country according to their supply, demand and security risks. The US is a particularly large consumer of critical minerals, because it has built a high-tech economy which relies upon semiconductors, electronics and power transmission. This in turn requires the US to import a variety of critical minerals to meet these needs.

The main challenge for the US is that large amounts of its critical minerals are supplied by China, meaning that the US is dependent upon their main competitor for critical items underpinning their economy. Visual Capitalist neatly illustrates how China dominates the supply of many of the US's critical minerals:

In particular, Gallium, Arsenic and Cobalt are critical minerals for microchips. China is the leading producer of Gallium, and produced 96% of global production in 2021. The US is pouring money into the research, development and fabrication of semiconductors in the US via the CHIPS and Science Act of 2022, but lacks the raw materials to manufacture semiconductors.

Why Does This Matter?

The challenge for the US is twofold:

- Increasing geopolitical tension throughout the world, including wars in the Ukraine and Israel, which add to years of hardening rhetoric between the US and China

- Wars have both highlighted the need for smart weaponry (e.g. cruise missiles, anti-tank missiles and drones), which rely upon high-tech systems and semiconductors, whilst also depleting US and European stocks of these weapons.

The result is that the US military is increasingly dependent upon high-tech weapons. However, the supply chain for most of these weapons is highly dependent upon both China (the US's current main competitor) and Taiwan (over which China asserts a national claim). Specifically:

- China dominates supply of some critical minerals, including Gallium, required for Semiconductor manufacture

- These minerals are shipped to factories, e.g. in Taiwan, where semiconductors are made

- Taiwan manufactures the majority of the world's semiconductors

- Manufactured chips are then shipped to purchasers, including companies in the US

- High-tech companies and defense manufacturers in the US use these chips to build products, including weapons

- US production of weapons systems is consequently dependent upon China

The result of this is increasing concern and tension in the US government as they realise that their Critical Mineral supply chains are a matter of national security.

Critical Minerals in the Subsea

Reserves estimates indicate that there are large amounts of critical minerals present in subsea minerals - for example, polymetallic nodules in the Clarion-Clipperton Zone, or Cobalt-Rich Crusts in the Prime Crust Zone.

Research by James Hein and the team at the USGS indicates that subsea minerals reserves are potentially significant compared to terrestrial reserves. For example, it is estimated that there is 206x more Cobalt, 14x more Nickel, and more than 4x more REEs in subsea mineral reserves than currently identified terrestrial reserves:

Source:

"Deep-ocean mineral deposits as a source of critical metals for high- and green-technology applications: Comparison with land-based resources"

James R. Hein, Kira Mizell, Andrea Koschinsky, Tracey A. Conrad

Ore Geology Reviews, Volume 51, 2013, Pages 1-14, ISSN 0169-1368

https://doi.org/10.1016/j.oregeorev.2012.12.001

Ensuring Critical Mineral Supply

Deep Sea Mining has a potentially huge role in ensuring a steady and secure supply of critical minerals to all countries. Specifically:

- Global Supply: Subsea Minerals are found in various locations around the World's Oceans, and so are accessible to almost all nations

- Various Jurisdictions: A variety of international and nation-state jurisdictions govern subsea minerals, including the UN (via the ISA), Norway, the Cook Islands, and many other nations. This potentially leads to broader global geopolitical balance

- Abundant Critical Minerals: Subsea Minerals contain vast volumes of critical minerals. Unlocking their production would reduce supply pressure and ease geopolitical tensions

Conclusion

Critical Minerals are a classification of minerals that countries rely upon to underpin their core technologies, which countries are dependent upon importing, and whose supply is restricted by various factors. They are therefore of utmost importance to a country's economy.

Whilst there are many different Critical Minerals, most are related to the production of high-tech equipment, including semiconductors, motors, generators, solar cells, and batteries. These products are often related to the green transition, and are experiencing rapidly growing demand combined with supply constraints.

Subsea Minerals present a potentially huge source of Critical Minerals, that often dwarfs terrestrial reserves of those minerals. Furthermore, the global distribution of Subsea Minerals combined with their governance under various international jurisdictions ensures that their supply could be balanced and fair between nations and world powers.

To this end, Susbea Minerals present an opportunity to diffuse geopolitical tensions whilst furthering the green transition.