Phillip Gales:

Good morning everyone! I'm pleased to be speaking this morning with Guido van den Bos from NOV.

Guido, can you tell us about how you got started in deep-sea mining and what your role is at NOV?

Guido van den Bos:

Actually, if you really pull it back, I studied geology in 1994 at the University of Utrecht where I also did my Master's. After that, I went to work in the offshore oil and gas industry in various roles at various locations, from Mexico to Malaysia to the Caspian Sea.

In 2005, I started with NOV, first on the drilling side, and then moved through the ranks working in Romania, Aberdeen, Poland, to various roles within NOV's corporate office. I got more acquainted with the corporate side, their roles and particularly developments, technology and innovations on the floater side.

Within NOV, we have the Energy Equipment side, where we focus on equipment for the (drilling) rigsite, and provide equipment and services for offshore wind. We also look at various areas where our expertise and knowledge can be used elsewhere, so we started moving into floating wind, we started looking at low carbon solutions like carbon capture and storage, and also biogas and energy storage subsea.

We asked ourselves, “hey, how can we utilize our technology and expertise in subsea engineering in different ways?” Because of that, deep-sea mining came onto our radar about four years ago now.

Phillip Gales:

That makes complete sense. Can you tell us a little bit more about the services, equipment and engineering work that NOV provides in deep-sea mining?

Guido van den Bos:

Yeah! So, on the upstream side of the business, we have the skillsets and capabilities to design vessels - not just the traditional SOV (Support Vessel), but all the way up to drillships, floating construction vessels and jackups.

The beauty is that we not only do the design phase, but we also have, of course, the equipment from offshore drilling. For example, topside equipment like pumps, derricks, winches, but also more subsea equipment like risers, flexible risers, drilling risers and on top of that, of course, drilling fluids.

"we have a long history in (offshore) upstream oil and gas operations, which are very applicable to deep-sea mining"

These are all aspects where we have a long history in upstream oil and gas operations, which are very applicable to deep-sea mining. You need to deal with fluids and ore slurries (in the sense that polymetallic nodules need to be separated from seawater in controlled ways), you're dealing with large volumes of fluids, large pieces of equipment to handle and to move around, the Production Support Vessel is moving, and it's operating in water depths beyond what is traditional in offshore oil and gas.

So, there's a lot of different areas where we can utilize that knowledge gained through offshore oil and gas, and that can be transferred. Then there's definitely a lot of engineering expertise on top of that which is transferable and that gives you a good basis to work from.

Phillip Gales:

Of course you're mostly talking about polymetallic nodules at this point, because most of the main players looking at harvesting nodules are using converted deepwater drillships and a lot of the associated equipment.

Phillip Gales:

What you're saying is that in order to convert a deepwater drill ship into a production support vessel, the riser itself, the riser handling equipment, a lot of the topsides equipment including the pumps, dewatering, etc., can all be based around drilling equipment that is then modified in suitable ways to deep-sea mining.

Guido van den Bos:

Yeah. When we first started looking at this, our philosophy was that it would be obvious to convert demobilised or distressed deepwater drilling units that had been cold stacked for a long time. That makes most sense from a CapEx perspective, it makes sense because they have large amounts of storage space, they have equipment for dealing with and handling risers.

So the conversion capacity of the vessel and the associated equipment is relatively good. Given the market dynamics, the asset availability and the way to market as an intermediate solution, yeah, then of course it's very obvious to use.

Phillip Gales:

I love this potential story for the start of the deep-sea mining industry - it's like a phoenix rising out of the ashes of the oil and gas industry - because these deepwater drill ships can be repurposed into deep-sea mining vessels and production support vessels.

"it's like a phoenix rising out of the ashes of the oil and gas industry"

Except you said that the drillships were cold stacked - because I think the day rates have now gone through the roof - like $4-500,000 per day for deepwater drillships! Are you seeing suddenly a pull back on that or are you think is this is this just a little blip that's going to overcome itself?

Guido van den Bos:

No, no. But you got that right.

Of course, back in 2015, that was a very dramatic downturn in the upstream oil and gas business. But in the last few years, the upstream business has definitely been coming back again, and you even see reactivations, repurposed units and warm-stacked drilling units coming back. Cold stack units are being considered to come back again. There are even some units in the yards coming back to the market, so there is a big uptick in the industry.

Phillip Gales:

Do you think this will impact the development of deep-sea mining then?

Guido van den Bos:

We're of course looking at the market going forwards and how that impacts deep-sea mining, but I don't think so because right now there's still units out there that are distressed. So, if there's a need for one for conversion there will be a possibility to do so.

There's already a few front runners out there looking at the market and doing that now - and that's not only in Europe, but you see it in in areas in Asia as well.

Phillip Gales:

So if I'm a deep-sea mining operator and I'm trying to pull together the equipment and I approach NOV, can you tell me a bit more about how you typically engage what you're sort of work is doing?

Guido van den Bos:

Yeah - it's a really good question because when we start an engagement with new customers, we always try to get a big white board (preferably a clean one, which is always difficult to find!) We start with the date of today on the top left, and where we are today. (We first started some of these conversation in 2020-2021, by the way.) Then the customer writes the date they want to operate in the top right, and you fill in the years between today and that date.

Normally you have a time frame of about seven or eight years or so - which seems like a long time - but if you start cutting that time up with the requirements they need - that's not much!

"Normally you have a time frame of about seven or eight years...but...that's not much!"

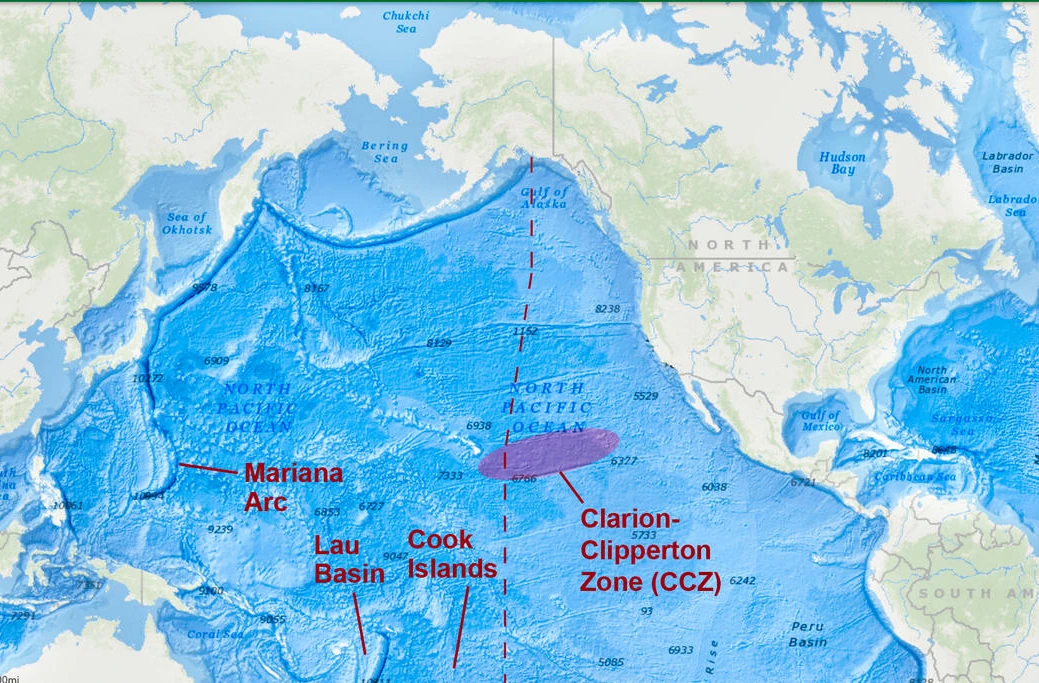

For example, to understand where their license is, to understand what they want, and then transfer back to our capabilities in vessel design and conversion capabilities of the unit itself. So, you start looking at whether a given vessel could operate in that location (for example the middle of the Indian Ocean, the North Pacific, or Norway) and would those conditions there affect the operability of such a unit giving its displacement and how it needs to be operating? And then on top of that, we started with nodules, but of course SMS and CRCs are coming into the play as well, which have different engineering requirements and needs.

So, you have to consider what is the client's business model, and what they are basing their business model on. For example, what kind of production rate they're looking at, what kind of harvester they plan on using, and then all the technical details of the vertical transport system - from what type of pipe, what diameter does it need to be, what kind of pumping do we need, what type of pump are we looking at? And then when the subsea minerals come to surface, how are you going to treat it? How do you want to store it? How do you want to offload it?

Suddenly you start drawing this complex picture. Then you start cutting it down to engineering requirements and lead times - suddenly that eight years is a very interesting time frame which actually doesn't give you that much time.

Phillip Gales:

So what are the challenges within that?

Guido van den Bos:

You start with the customers business model and the level of uncertainty in that business model. For example, what is your production rate?

We start with that and then we start looking at the design, because engineering hours can be eaten up by a lot of iterations and modifications. Example, are you going to do a harvester with a riser? Are you looking at containerized skip lift principle? What kind of offloading are you looking at? Are you contracting? Do you have a unit, or you don't have a unit?

Then once you have that, you need to have a FEED study to really start filling out the details and the structure. Of course, there's other parties like the collector systems, or other parties that have engineering needs and requirements. You bring that back together, and once that's finalized, then you start looking at what the lead times are if you need to build or convert something - are we talking two years or 18 months? Then once you have it, you need to install it, commission it, and then you have to wet test it.

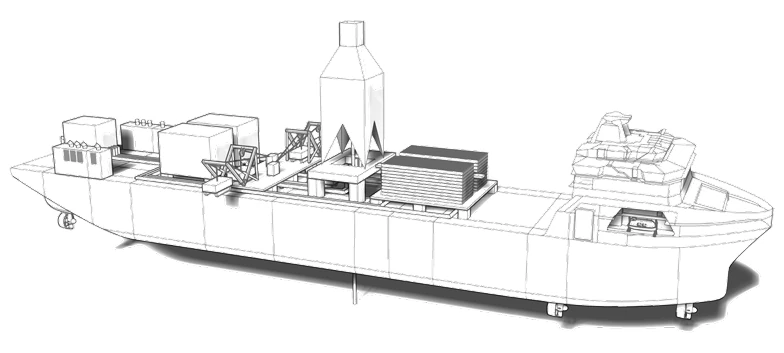

NOV schematic for a production support vessel

NOV schematic for a production support vessel

Phillip Gales:

So it sounds you've got this puzzle where the pieces are continually moving.

Then I assume that things happen where say, the client wants to have two harvesters operating simultaneously? You have to figure out the engineering work for two harvesters on the production support vessel - but that means a bigger riser and different dewatering equipment. I can imagine you getting into this complex engineering loop where you start to learn more stuff and have to iterate around it to then figure it out from there.

Guido van den Bos:

Yes, yes - exactly.

Phillip Gales:

What are the most interesting engineering challenges for you in deep-sea mining?

Guido van den Bos:

I really liked it when we started working with the engineers, and we started looking at new product development requirements for deep-sea mining. It was an exciting new challenge.

The engineers came with this massive “backpack” of engineering experience from their time in upstream oil and gas. They've seen large deepwater units being used on location, and of course, in oil and gas we're very aware of environmental needs like zero discharge. The question became how we could best transfer that knowledge, expertise and technologies from oil and gas to deep-sea mining.

"(the) engineers came with this massive “backpack” of engineering experience from their time in upstream oil and gas"

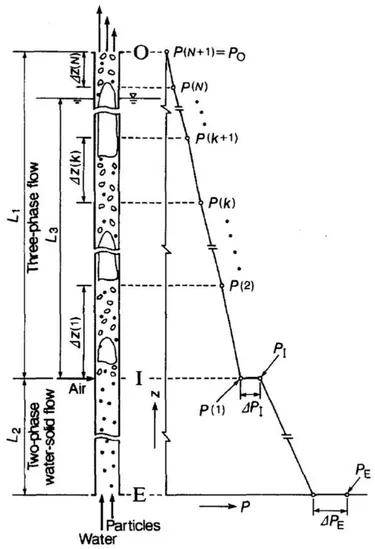

For example, to make impact-minimum designs in things like the vertical transport system, we wanted to do it with existing footprints and equipment. So, our approach was to have surface pumps, instead of subsea pumps or an airlift system. Then we started to do the fluid dynamics modelling and finite-element analysis - it took a lot of computer power so to say to do that! Then we had more comfort around how we can make it closed loop - but suddenly a new piece of IP has to be invented by engineers to overcome challenges - so new ideas spark new ideas, but sometimes it's a dead end road, you have to come back and take another turn.

That took a while to find the right balance - you can make the riser as big as you want - but it still needs to be pulled up at some point into the vessel. Gravity and buoyancy are a friend and the enemy sometimes!

But then there's the interaction of it, right? For example, how does it transfer the weight (to the production support vessel) and what are the dynamics? So, you start doing riser analysis, you do naval architectural, balanced marine behaviour etc.

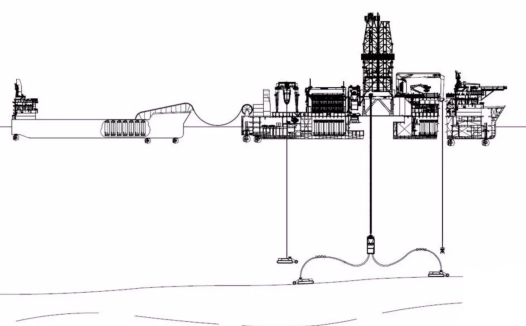

NOV schematic of a production support vessel, with two harvesters deployed, offloading to a bulk ore carrier

NOV schematic of a production support vessel, with two harvesters deployed, offloading to a bulk ore carrier

Phillip Gales:

I'm laughing because when I first looked at the riser, it just made sense to me - it's a bit like a deepwater drillship riser.

Phillip Gales:

Running 6,000 feet of riser for a deepwater drill ship is challenging, but it's not 6,000 feet in deep-sea mining it's 6,000 meters! So it's three times as much!

Then in deepwater drilling you've got heavy mud inside, so it's a burst resilience calculation. But in deep-sea mining you've got a mixture of air, nodules and seawater, so it's a collapse resilience calculation. And in deepwater drilling your riser is heave compensated because it's fixed to your BOP, but in deep-sea mining (or at least, the Hidden Gem) it isn't heave-compensated.

It warped my mind when I started thinking about all these differences.

Guido van den Bos:

And that's the beauty of construction in the offshore world, that there is a lot of experience dealing with large projects and large items of equipment, and people are not afraid to deal with it. But if you're not used to, or have not been exposed to this industry, then it might be indeed scary or mind-blowing.

Guido van den Bos:

Don't get me wrong, but the exceptionality of dealing with large items, heavy lifts, the engineers and especially the operating people - it's just amazing.

Phillip Gales:

You touched on some of the ore offloading aspects, like slurry offloading and conveyor offloading. Can you tell us more about ore offloading and shipping? Because that's a difficult engineering challenge.

Guido van den Bos:

It is, and of course we've discussed this at length within the industry, partly because there's two ways to go.

One option is wet - you keep the nodules in a kind of a wet state, and you pump them in a slurry. The other option is dry offloading - where you are more looking at a conveyor-belt based system.

Both are challenging, and of course, we're working with a class provider like ABS or DNV to get a sense of what is allowed, what's possible, and how can we do it as wisely as possible.

Then there's the distance. Some potential locations for subsea mining are very remote, and it takes a long time to go back and forward. So, in order to be efficient, you probably need to have the largest sized bulk ore carriers operating out there - for example the Panamax size - which has a lot of storage space. But that then is another regulator matter, to make sure we do everything the right way.

Example of alongside transfer at sea

Example of alongside transfer at sea

Example of hose offloading from an FPSO

Example of hose offloading from an FPSO

Example of conveyor offloading for iron ore

Example of conveyor offloading for iron ore

Phillip Gales:

If we look into the future, how do you think this this industry will be operating?

Guido van den Bos:

Let's just consider the Pacific. It's important to realise that vessel size really does matter in those kinds of remote areas.

Partly that's for the people onboard. Upfront, people probably will have to do longer rotations on the Production Support Vessel than are typical for offshore operations, because it's so remote. So, you need to make sure that there's a good work and living environment there, and vessel size definitely helps in that. Partly that's the size of the accommodation, but it's also about stability in adverse weather conditions and storms.

If you do have a large vessel, then of course storage becomes a big positive factor. Larger storage means that there's less need for supply vessels or bulk ore carriers to go back-and-forth, which helps with logistics and simplifies operations.

"vessel size really does matter in those kinds of remote areas"

Once you have that foundation, then you can start looking at how can you make it as clean as possible. That is, clean in emissions and power usage via digitalization and innovation and data transfer.

Then you start looking at how can we make it lower-carbon operation and how can we utilize digital information, automation, and robotics. Fundamentally, how can we utilize these to have as few people on board as possible. If you can easily send data back and forward, then operations might be even overseen by an office-based operator, right?

Looking at the operations, it's a very hard environment to work in, and it's rough on equipment. So then predictive maintenance comes into play. We can use big data to understand when equipment needs maintaining or replacing. And then we get into possibilities where even the cargo vessels right, they can be battery-powered, or they can have hybrids.

"it's a very hard environment to work in, and it's rough on equipment"

It's all technology that is already out there, so it's possible to make it as clean as possible because shipping is one of the bigger impacts in transport as a whole in emissions. So how can we already kick start that from the from day one?

Phillip Gales:

Just to be clear, we're talking mostly about polymetallic nodules and really we're talking about the Clarion-Clipperton Zone here. You've raised a lot of points, but one is just the immense remoteness of that location.

I started looking at this and I thought it was going to be like the Gulf of Mexico, maybe 100 miles away, but it's not! It's between 500 and 2000 miles from the nearest land. With that comes tropical storms, and bad sea state. You made some really great points about what you need - a big stable vessel - and that people are going to be on that for a long period of time. So, it has got to be safe, and it has got to be reasonable for them to live on.

But then the other point you made as well, is that we live in the digital age. We'll have a lot of information flowing from the Harvester, from ROV's, and from monitoring systems. So how can we use that data, how can we transmit it to shore, and then reduce the amount of people needed out there on the Production Support Vessel?

Guido van den Bos:

Right.

Phillip Gales:

If you have remote ops then you can have people onshore operating the harvester via a data stream. Then suddenly you reduce the number of people out on the production support vessel. So, you reduce the impact, you reduce the number of flights, you reduce the required size.

Phillip Gales:

Obviously deep-sea mining has a very, very different risk profile to deep water drilling. Specifically, you don't have oil and gas under pressure. But you still have heavy equipment, you still have lifts, you still have trips and falls, et cetera.

So what do you think from a safety perspective, the deep-sea mining industry can learn or can adopt from the deep water drilling industry?

Guido van den Bos:

I would say a lot, of course. You already see various drilling contractors implementing a range of technologies on the digital and automation fronts. You also see red zone areas and camera visuals that will instantly stop if, for instance, if people walk onto the drillfloor. We also have now robotics for installing risers.

This is right now - it's not pie in the sky anymore - that technology has come to drillships today, where optimization is there, and a driller is just overlooking the operation these days. It's proven technology even, which is now relatively easily transferred with a few tweaks that will suit the deep-sea mining industry and contractors.

Phillip Gales:

I think that's really great.

The other big difference we haven't mentioned with oil and gas is that when you're drilling you're continuously pulling or tripping pipe, you're continuously turning the bit, it's continuous dangerous operations even though it's not to do with hydrocarbons.

Pipe handling operations on a deepwater drillship in the oil and gas industry. This is a common activity involving heavy lifts, that is clearly a significant risk to the crew involved.

That's something I really love about the deep-sea mining industry, because you don't have these continuous dangerous operations and heavy lifts - you've just got a harvester in the water on an umbilical!

Guido van den Bos:

Yep.

Yeah, that's probably the one thing that will come up and down on a regular basis, but that's an on umbilical, attached to a big A-frame at the side of vessel. It's very controlled moving through the splash zone and around on deck.

Phillip Gales:

That's already automated as well, right?

Guido van den Bos:

Yes - so that's nobody in harm's way.

Phillip Gales:

And then I assume the riser could be down there for months.

Guido van den Bos:

Yeah, it's in that range we can even talk about.

Phillip Gales:

So in terms of actual heavy lifting of equipment, obviously there's running the riser, and there's running the harvester. But beyond that, it's not the same continuous lifting, continuous pipe-handling, or continuous high-pressure pumping that happens in offshore drilling operations. So, there's a lot less going on, and it's a lot safer.

Guido van den Bos:

Yeah.

Phillip Gales:

There's so many things I love about this industry, but the fact that it's so comparatively safe is tremendous..

Guido van den Bos:

Exactly, because even if you start looking at the process of offloading bulk ore, it will be automated, so there will be no human exposed in any way.

It's a matter of controlling vessels alongside each other, and that's proven today as well, that's nothing new either.

For an outsider, it looks very scary to large vessels, but then again saying that it's there, the technology is there to overcome that to make sure that's not going to happen.

Phillip Gales:

Are there any areas that that you'd like to talk about or any questions you'd like me to ask you?

Guido van den Bos:

I definitely want to say that we all know that deep-sea mining is controversial for certain people. But I also definitely want to make it clear that from day one of NOV looking at this industry, we've been asking what we can bring to the table to make it as safe as possible for humans, and also for nature, right.

That's why we're looking at zero discharge risers, lift systems that have minimum wastewater returned to the ocean, and we all know that the collector design companies are looking at how to minimize and reduce sediment plumes.

So, our engineers look at what we can do with the technologies to have to make sure we do the right way, and otherwise we won't do it.

Phillip Gales:

I think you've raised some really powerful points there.

One is that in many ways, this is an engineering challenge. If you can understand what the environmental impacts are then you can find engineering solutions to those.

Guido van den Bos:

Yep.

So that's the philosophy, and that's what I like the most about this industry - the openness to think differently.

And the beauty of it is that we don't have to start from square one or from scratch, right? Because we are already a few levels up. We can already learn quickly from previous designs and implement rapidly.

Here's the funny part though - we had documents in our basement from back in the 70s that already had drawings, statistics and sketches of certain riser developments.

Guido van den Bos:

So seeing that coming back again and then, yeah, and well, what I really love is the engineers working on this and having them diving into a new challenge. It's worth a challenge because these matters can be solved.

Phillip Gales:

I did have one last question, what should the world know about deep-sea mining?

Guido van den Bos:

I think the facts, purely the facts. There is too much emotion involved.

Of course, is right to have an opinion, as long as the discussion is based on the same facts. But if you start cutting out facts that are undisputable facts, you start to dispute them, then it's not going to be a conversation anymore, because then it's polarized.

But we do have to realize that if you start looking at terrestrial mining, then yeah, it's difficult.

If we want to build the world today with the Paris agreements inside in 2050, then the amount of renewable requirements, the efforts we need to take towards solar power, wind generation, carbon capture and all the efforts to do more electric cars and transportation - it takes a lot of “Lego blocks” to build that.

It's not going to happen by just stopping oil and gas.

Phillip Gales:

I think that's something that is missing in this discussion.

We can all sort of agree that it would be nice to drive a nice electric vehicle that's got a good range, where you get in it, you've got your nice mobile phone and you have an AI system that helps you with your route.

But we're not going to be able to do that if we don't have the Lithium and the Cobalt for the batteries. If we don't have the Scandium or Gallium for the microprocessor.

Guido van den Bos:

Exactly. That takes a lot of “Lego blocks” of critical minerals in order to do that.

Phillip Gales:

Exactly. Guido, this has been absolutely brilliant - thank you very much for your time!