Deep Sea Mining Equipment and Components

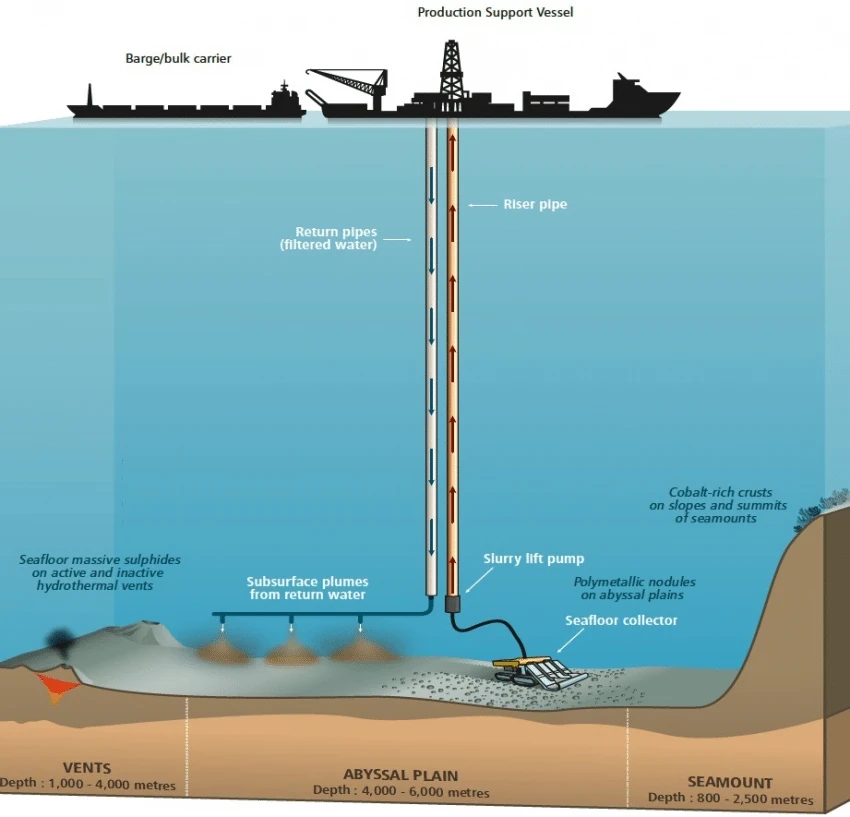

Deep sea mining for polymetallic nodules requires a number of items of heavy equipment working together efficiently in order to successsfully and safely collect and store the nodules.

At a high level, the discrete steps are:

- Collection of the nodules from the seabed at depths of around 6000m via a collector

- Transport of those nodules from the seabed to the Production Support Vessel (PSV) up a riser

- Separation of the nodules from water

- Storage of nodules in the hold of the PSV (and eventual offloading into a bulk ore carrier)

- Return of the water component back to the depths of the ocean

- Offloading of nodules to a bulk ore carrier

Each of these processes requires specific equipment, below, namely:

- Production Support Vessel

- Subsea Collector

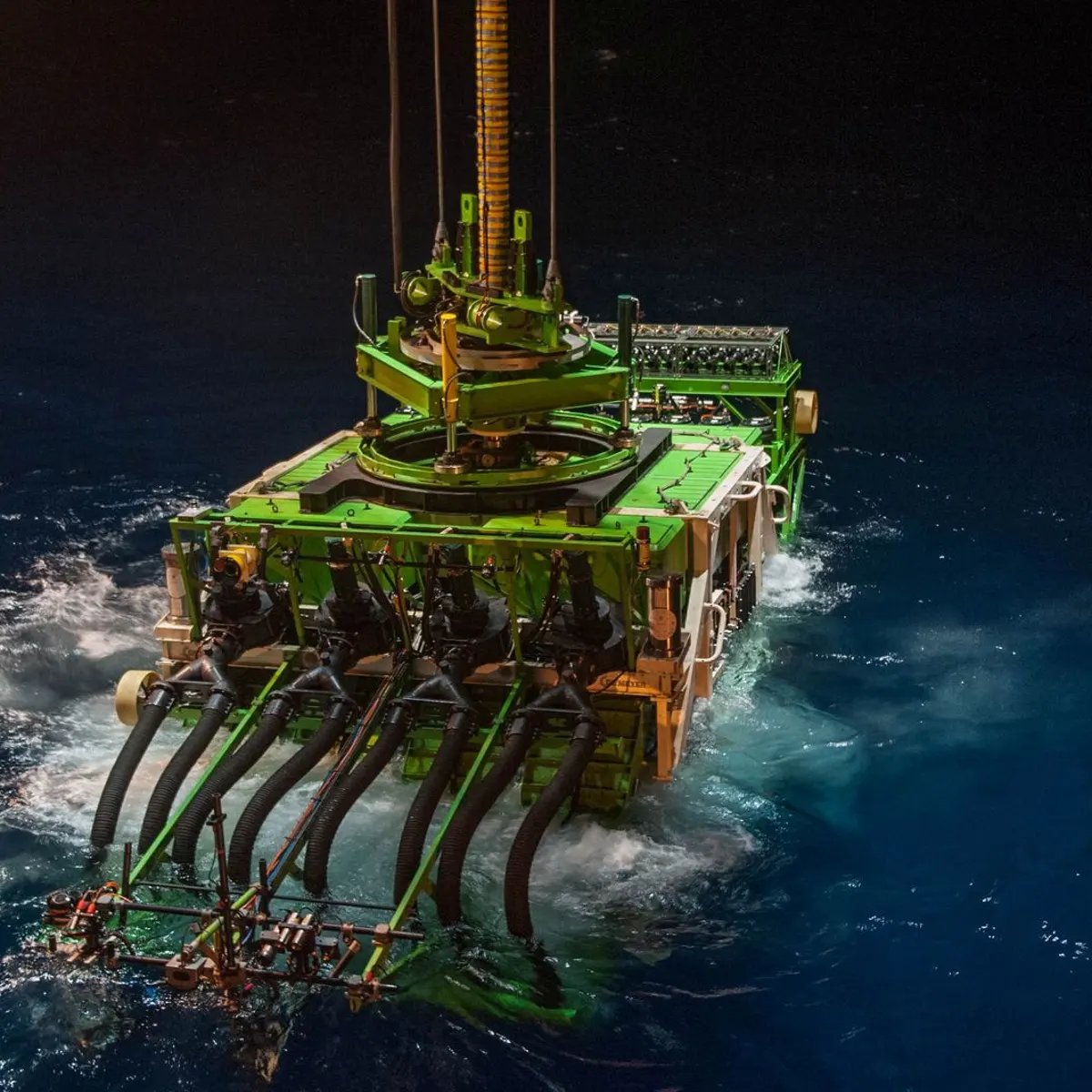

- Collector Launch and Recovery System

- Riser joints on the riser deck of the PSV

A Production Support Vessel (PSV) is the main facility for collecting, gathering, lifting and storing polymetallic nodules. They are typically modified from dynamically positioned deepwater drillships from the oil and gas industry.

The PSV typically provides the platform from which the Subsea Collector is operated. The Collector is lowered to the seafloor via the Launch and Recovery System (LARS), which is located on the side of the PSV. The drilling derrick of the PSV is used to lower the joints of riser in order to build the Riser Air Lift System (RALS), which is used to lift the polymetallic nodules from the seafloor.

The PSV provides power for all this equipment from a set of diesel engines driving electric generators. These also provide power for the dynamic positioning system, which uses azimuth thruster pods to hold the PSV steady at a fixed position in the sea. Finally, the crew monitoring and running the operations are all housed in a large accomodation module, with a ship's bridge on top, and the helipad slighlty forward.

These are huge vessels, with tremendous power capacity, enormous holds, and living quarters for a large crew:

| Dimension |

Value |

| Beds: |

120-200 |

| Length: |

200-260m |

| Breadth: |

40-45m |

| Tonnage: |

50-70,000t |

| Capacity: |

30-100,000t |

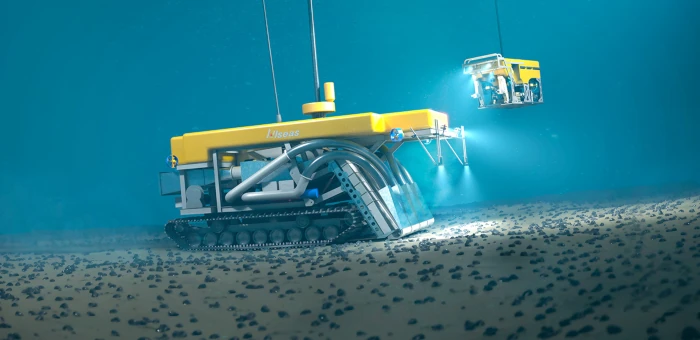

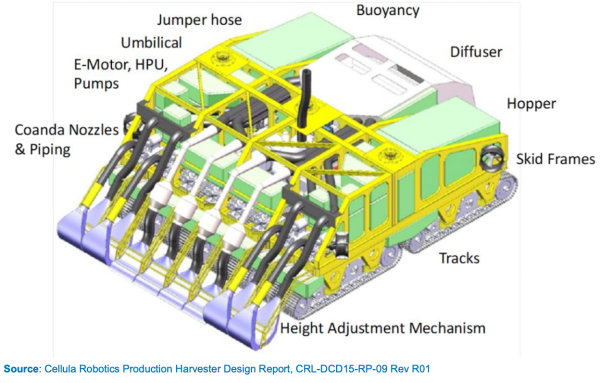

A Subsea Collector (sometimes called a 'harvester' or 'mining vehicle') is an underwater vehicle that moves along the seabed collecting polymetallic nodules.

Each PSV is equipped with one (or more) subsea collectors. The PSV provides power, control and other functions to allow the collector to operate. The collector starts on the surface on the PSV, and is slowly lowered down to the seabed using the Collector Launch and Recovery System. A large umbilical cable provides power, communications and control to the subsea collector, so that it can be monitored and guided from the surface on the PSV.

Subsea collectors use a variety of different proprietary technologies to efficiently pick up polymetallic nodules from the seabed. These may involve complex hydraulics, mechanical equipment, or robotic collector arms. Each method has different advantages and disadvantages, and may cause more or less impact on the fauna of the abyssal plain.

The subsea collector slowly moves along the seabed collecting nodules, and typically uses caterpillar tracks for propulsion.

Riser Air Lift System

A variety of different methods are used to lift nodules to the surface, but Riser Air-Lift Systems (RALS), using pumped air to reduce the buoyancy of the water, are the most frequently used.

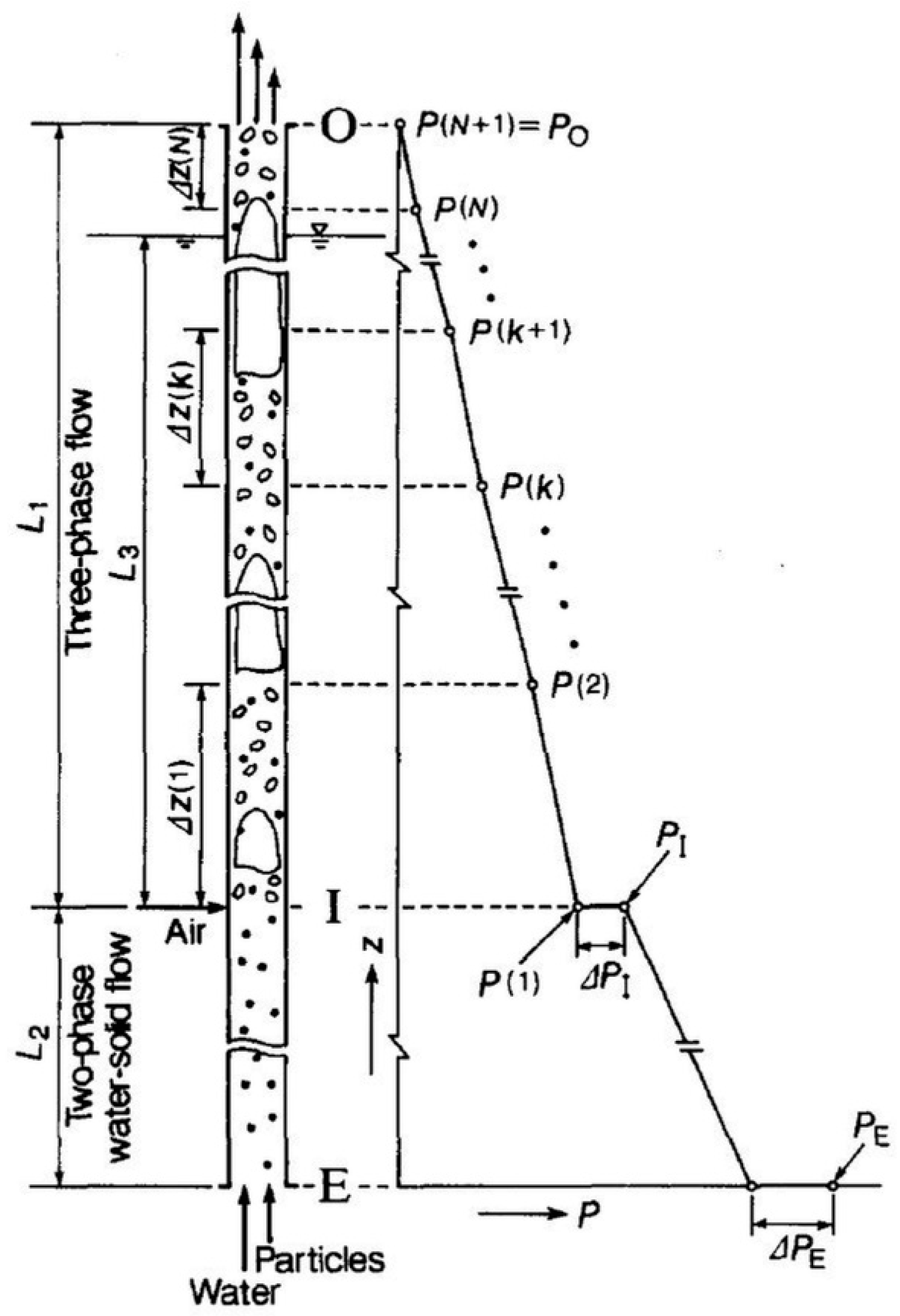

The RALS is used to lift the polymetallic nodules from the seabed where they have been collected by a collector, up ~4000-5000m, to the Production Support Vessel (PSV) at the surface. Air is pumped from the PSV down a secondary line on the RALS, to approximately two-thirds the depth of the RALS. Here it mixes with the two-phase mixture of water and polymetallic nodules coming from the lower part of the RALS. The air creates a lower-density three-phase flow comprising solid nodules, liquid water and gaseous air.

If sufficient air is pumped into the RALS, then the density of the three-phase flow flowing up the RALS is reduced to the point at which the pressure of the hydrostatic column inside the RALS is less than the pressure of the column of seawater outside the RALS. At this point, seawater flows into the bottom of the RALS, creating an upward pressure on the column, and causing it to flow upwards. If this upwards velocity exceeds the settling velocity of the nodule particles, then polymetallic nodules will flow to the surface.

Unlike most deepwater drillships, the RALS is not heave-compensated, and moves vertically with the heave of the PSV as it moves up and down in the crests and troughs of waves. This may create a variety of problems, including significant loads on the RALS and anchoring equipment; harmonics in both the RALS and the hydraulic column; and significant operating limitations in heavy sea states.

Further issues with RALS including slugging of the flow. This is where the gas, liquid and solid phases separate out (either during dynamic flow, or when flow stops). Flow at the surface then alternates between "slugs" comprising almost entirely of air, water or nodules. The result is that surface equipment may be overwhelmed by the suddenly varying flow received (see the TMC "cyclone separator overflow" for the typical results of slugging).

RALS are typically stored on the PSV riser deck, then run using riser handling equipment using the drilling derrick.

Surface Separator Equipment

Three-phase flow received at the surface at the PSV must be separated into water, nodules, and air. This is done using separating equipment, typically comprising a centrifugal separator and modified drilling shakers.

A centrifugal separator (see above) is used to coarsely separate nodules from water. Fluid enters the circular separator at an angle, flowing around the edges of the circular separator. Centrifugal force causes denser material (specifically nodules) to migrate towartds the outer part of this flow, whilst less dense material (water) remains towards the centre. The outer part of the flow is separated from the central flow.

A second separation stage using shakers (see above) further separates and dries the nodules. The partly concentrated flow of nodules and water from the cyclonic separator in the previous step flows over a series of coarse metallic screens that vibrate vertically and horizontally. Water flows through the screens, whereas the nodules stay above the screens and flow off at the end. Separation is highly efficient.

Polymetallic nodules are transferred to the holds of the PSV using a conveyor belt. Separated water is returned to depth using an auxiliary line in the RALS, which ensures that the impact on the ecosystem is minimised.